Kithomebasics Gallery

Shown is a collection of graphics, pictures and links from the kithomebasics site.

Kit home building time lapse

Kit home delivery was the end of a 3 month process of buying land, choosing plans, fire, water and termite plans, owner builder course, finances and insurances.

Building a raised floor using piers instead of a slab was a better solution for owner building. Working off the ground is better too.

Standing wall frames was relatively easy, although lots of 'plumbing' is required to get and keep them straight.

A straight through gable roof is the simple way. Installing a truss roof took some thought, but there's lots of systems that can assist the process.

Truss bracing and gable ends were the last tasks in the roof framing process. The verandah skillion roof frame and decking were then added.

More info....

Installing metal roofing proved a challenging task. Here are some good tips to get a lid on your kit.

More Info....

Flat pack kitchens are a great option for the owner builder. Great outcomes and good looks and nowhere near as difficult as it looks.

More info....

There are many ways a bathroom can be designed, and in kit homes, small bathroom design is crucial. Supplied PC items are usually easy to install, as a rule.

External wall cladding for owner builders means weather-board or fibro-cement, rather than brick or block.

This style of kit is the most commonly erected, but there are many types of kits available including yurts, a-frame, modular, octagonal, pole, cabins, barns, domes or steel frame.

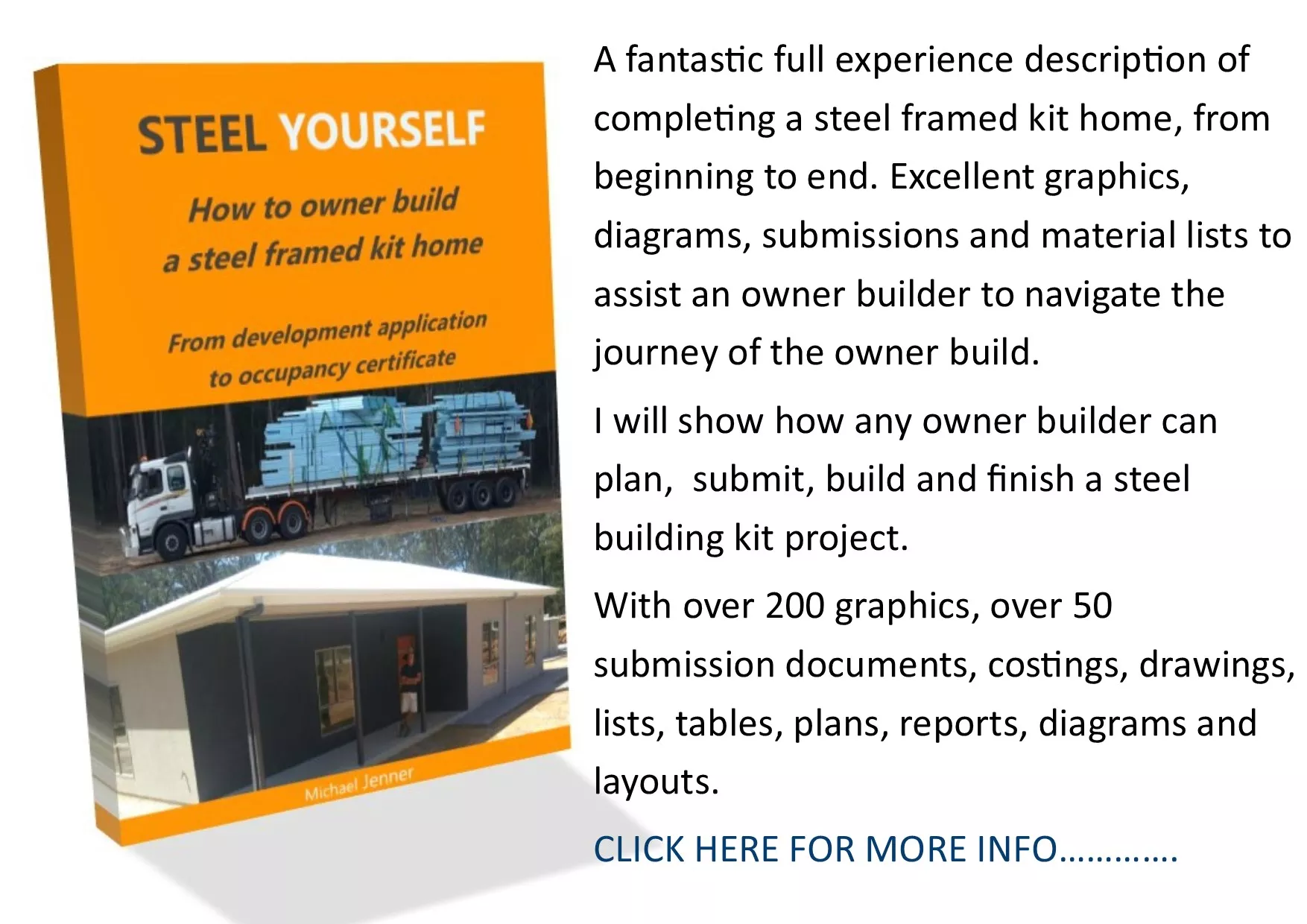

Steel wall frame construction for the kit home owner builder, from delivery to completion. More info....

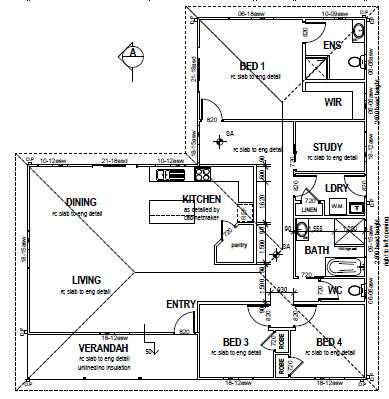

New steel home construction requires 4 or 5 sets of plans: a floor plan, framing plan, ceiling frame plan, roof support and roof panel plans as well as tie down specifications.

Building a steel framed roof requires ceiling, roof support and roof panels installed, all pre-fabricated by the kit home builder.

An ebook describing the complete journey of my owner building a steel building kit. Included is an itemised account of submitting a development application as well as material inventories, plans, designs and graphics.

From land purchase to move in, this is an owner builder 'must read'.

Foundation graphics

Setting out foundations can be done by the owner builder, with a little research. Seeing it done does help but the basics can be learnt.

Digging pier holes for raised floor footings required a few basics, a good excavation operator and simple tools.

Pier footings on a slope require some good soil testing and pier support design.

Slabs on a slope need cut and fill setups.

Tying a stud wall to a concrete slab, careful excavation, reinforcing, tie down bolts, compacted earth: all part of concrete footing design.

Constructing slab formwork for a kit home is not for the feint hearted and, depending on your background, may require specific assistance.

There have been many types of piers used over the years including those made on site: brick or block. But modern galvanised piers can now have a threaded spigot to adjust up and down to get them exactly right.

Here is a concrete slab construction pictorial from setout through formwork, pouring and finishing.

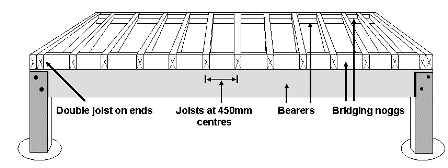

Raised floor

A raised floor system is a great option for the owner builder. Setting bearers on piers is the next step.

Laying floor joists on bearers requires a floor joist span table.

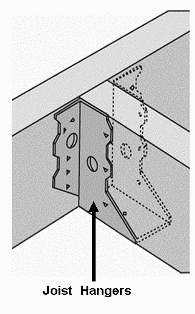

Once joist spans are set they can be installed on top of bearers or with joist hangers. Bridging nogs are used to stablise.

Easy design floor sheeting is now available. They are tongue and groove, waterproof and pest resistant.

More info....

Installing floor sheeting requires a two or three important tasks, but is a relatively simple task.

More info...

Wall Framing

Kit home frames come ready to stand. It takes a few tricks like stop blocks on the edge to begin though.

It's really a one person operation to stand wall frames. One of the easiest tasks really.

Anchoring the frames to the bearers holds them down and requires galvanised threaded rods, washers and nuts.

Understanding how a frame is constructed is useful for the owner builder, especially if minor alterations need to be made.

Standing steel wall frames, especially the exterior ones, is difficult due to their size: some are up to 6 metres.

Roof Framing

Standing trusses on wall frames requires solid propping and temporary bracing ties. A truss gauging rod is useful to.

More info....

Roof trusses need to be be attached to internal wall frames with sliding brackets to allow some vertical movement.

More info....

After the trusses are settled onto the wall frames, galvanised cyclone ties secure them to the top plates.

One of the last tasks of roof framing is the gable end studs.

Lastly, speed bracing set diagonally along the trusses connects the roofing frame to the wall frames and locks the roof together.

More info...

Steel frame roofing is a completely different animal. Roof support panels and lay over roof frames.

Roofing

Selecting insulation for installation under the roof revolves around maximum thickness, reflective value and gap-less fitment.

Gutter systems are very easy to install and have 'click to fit' galvanised and color-bonded components.Edging sections make it easy to make neat corners.

Guttering profiles range from contemporary square forms to classic colonial styles.

Galvanised roof batons come in 6 meter lengths and have a lip on both sides to screw them down to the truss top chords.

Battens need to be spaced no greater than 900 mm apart along the truss top chords, starting 100 mm from the apex.

Installing metal roofing on a truss roof is straight forward, as long as the roof is a gabled style. If it has valleys and more complex roofing styles, get a roofer.

Lots of profiles and all can be color-bonded. Ridge capping and barge capping edges and finishes the roofing.

More info....

It's good to gain knowledge of gable end profiles before you start. The barge capping completes the waterproofing of the last roofing panel.

More info....

Cladding

House wrap or vapor lock sarking prevents moisture movement behind the cladding.

External wall cladding for owner builders means weather-board or fibro-cement, rather than brick or block.

Another option is external Blueboard cladding, a 7mm thick fibro product designed to give a monolithic look to your house. Have a look at how I installed mine.

Applying render for novices: my complete description of sourcing, mixing, applying and finishing external cladding render.

External & Internal Doors

Exterior door installation requires the standing and securing of pre-hung door-jambs and doors. The joist requires some checking out but really a good challenging owner builder task.

Interior doors are also relatively easy to install with the supply of pre-hung doors. They arrive with hinges installed on the stiles and doors.

More info....

Gyprock/Drywall

Internal ceiling battens look similar to roofing battens and are secured to the bottom chords of the trusses with roofing screws.

More info....

Drywalling, plastering, gyprocking, call it what you like, it is a complicated and laborious task for the owner builder.

A full 3 bedroom house can be completely drywalled (inclusing the ceiling) in a few days by professionals. Add two weeks for the owner builder.

More info....

Jointing and plastering compounds are fun to apply but it takes time to perfect, feather and finish the joints and corners and get straight walls.

More info....

Kitchen

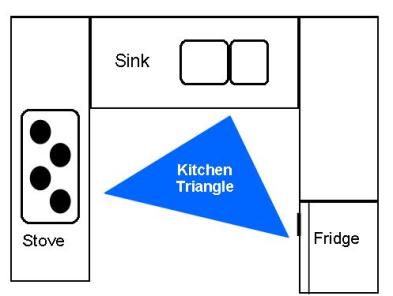

Kitchen balance describes a kitchen that allows ready and convenient access to the key facilities.

More info....

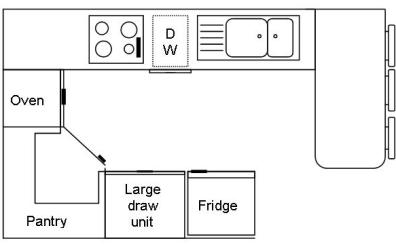

Small kitchen design can be challenging, but achievable with today's options.

More info....

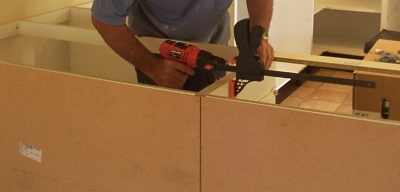

A flatpack kitchen arrives, you unpack it and then you sort it out. The beginning of a great adventure.

Kitchen carcases are pre-drilled and ready to assemble. Good plans come with the pack.

Flatpacks don't have to be boring. Large drawer units, pantries, trash units and corner carousels are now the norm.

More info....

Creating a line of cabinets requires a few basic tools and plans.

Kitchen counter tops come in standard melomine right through to stone and marble.

More info....

A kit home kitchen can have all the attributes of a standard built home kitchen, and look just as good.

More info....

Bathroom

Designing bathroom layouts is usually the domain of professional planners, but with a list of planning criteria at your fingertips, your bathroom floor plans can become a fully functional and practical bathroom.

The professional application of waterproofing compounds to bathroom floors, shower walls and edges, gives a secure moisture barrier for wet areas.

Setting out a bathroom for tiling requires a number of preliminary measuring tasks to begin and stay straight.

More info....

Tiling a shower with a hob is achievable for the owner builder.

Hobs add style and function to showers and framed and frameless shower doors modernise bathroom areas. Shower door specialists can create the effect you desire.

There are many tile floor patterns you can use, if you are game, and the outcomes can be excellent. It requires constant attention to lines and angles and a keen eye as well.

Checking out studs to fit a solid shower base allows base tiling to cover the lip of the shower base, increasing waterproofing.

More info....

Solid shower bases feel like tiled concrete, only better. They are easy to install and look great.

More info....

A Walk in Shower is a great addition to a bathroom and this series will show you how to create a shower floor and design your dream shower.

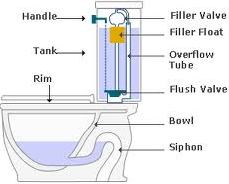

Toilets

Knowing how to install a toilet will assist you as an owner builder, whether you install it yourself or get the plumber to do it.

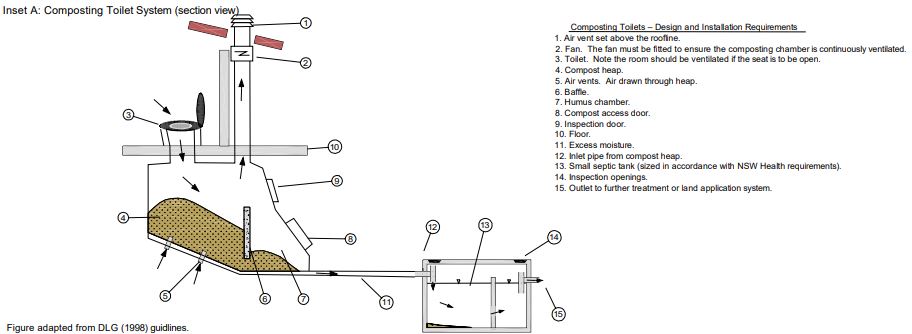

Composting toilet systems are aerobic processes that treat human waste, without water, using decomposition. Systems are mostly purchased in kit form.

DIY Projects

I built this ladder clothes dryer after finding my oregon pine ladder in

storage and wondered if I should throw it out or use it. More info....

Re-purposing ladders for shelving is a great way to use old stuff in the shed.

A ground level deck doesn't have foundations, so by design, can be mobile, even portable. With the changing of the seasons, a mobile setup can work well.

More info....

Trying to find decent jewellery organizers is a common problem of today's be-jeweled woman as most require a bench, shelf or table to stand on.How about window shutters?

More info....

An ugly duckling home renovation appears on our TV screens a couple of times a week, but I took on a unique challenge when I bought this almost dead kit home in Gympie.

How about these platform stairs built from pine sleepers. The are very practical and relatively easy to built. The complete build is described.

Pergolas

Rafter brackets assist pergolas to attach to flimsy modern fascias.

Attaching pergola joists to the top plates with joist stirrups is the best setup.

Installing a colorbond roof, gutters and downpipes onto the pergola finishes it nicely.

A wooden pergola finishes a house beautifully.

A finishing touch to my steel frame kit home was a wood heater installation.

Return to Kithomebasics home page